Student Work | Mass STEM Hub

High School | Engineering | CIM | Automated Guided Vehicle | 1st Place High School Engineering Project

May 26, 2022

Check out the student work submitted for real-world industry feedback! Learn more about submitting student work to receive real-world feedback here!

Grade: High School

PLTW Course: Computer Integrated Manufacturing

Submission type: Activity: Automated Guided Vehicle

Project overview: In PLTW Computer Integrated Manufacturing, students will learn about how all of the products they use every day are manufactured—from the product design to the manufacturing processes that involve robotics and automation. Students will earn to use computer-aided design (CAD) and computer-aided manufacturing (CAM) as tools to design and create products. Finally, as part of a team, they will design, build, and program their own manufacturing system model.

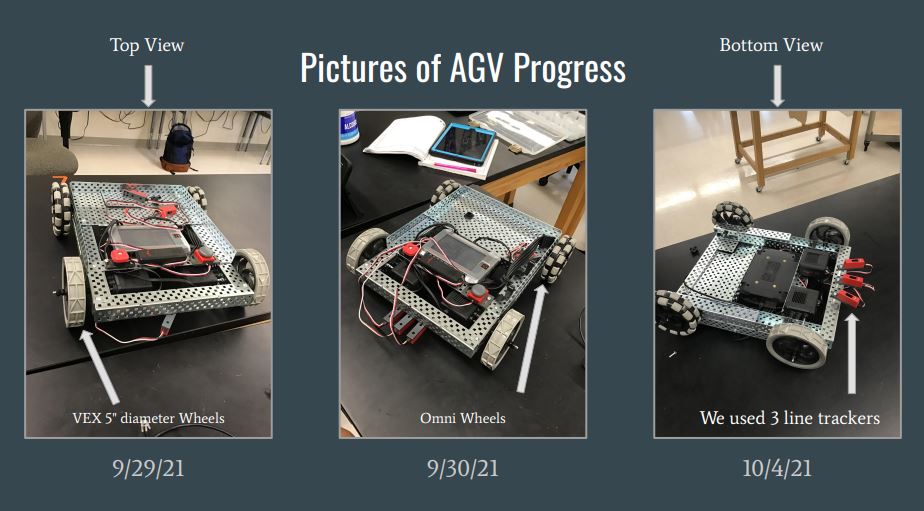

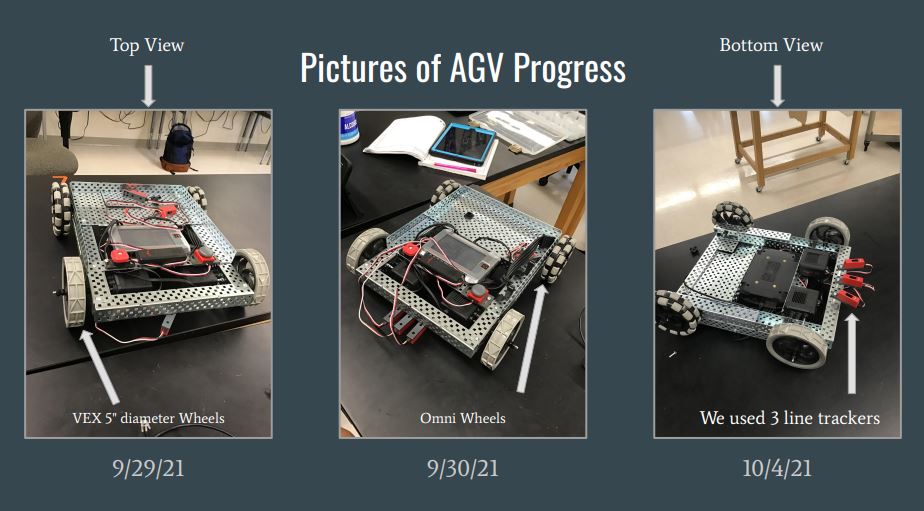

Prior to this project, teams will have gone through an entire unit on machine control. They will be very familiar with the robotic programming software, sensors, and other robotic equipment that was available for them to use. Students were asked to work in small groups to design and create an Automated Guided Vehicle.

Select student submission materials:

Link to full project: click here

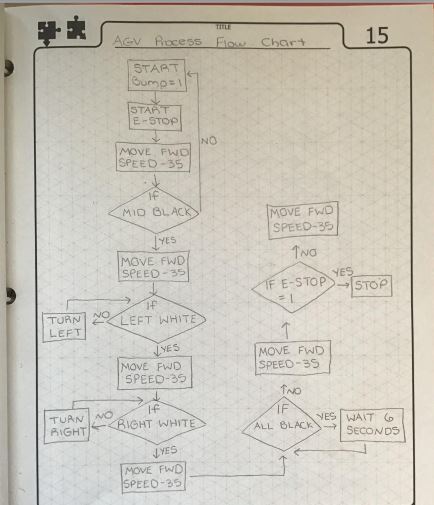

Select Judge Feedback: “Congratulations on your great work. This is the cleanest submission that I’ve come across. Your submission is easily understandable, your pictures clearly show what you want them to, your flowchart is easily readable and makes sense, and your notes are show clear observation and understanding. I’m really impressed with the quality of this work. Also, nice penmanship! This might all sound trivial, but the ONLY reason we, as engineers, write down information is so that it can be retrieved and used later. If this information isn’t neatly and clearly written and can’t be understood, then it’s worthless. We’ve all experienced not being able to read somebody else’s work. Imagine if Einstein scribbled down his theories and then couldn’t explain or understand his own work later. Weird example, maybe, but the point is – neatness counts!

Now on to the technical stuff. Your design is crisp, doesn’t seem to contain unnecessary steps, code, or components. This is what we refer to as an ‘elegant’ solution. It contains no superfluous parts or information that can confound troubleshooting or effectiveness. One thought I had is whether you needed three sensors. My takeaway, if I understand correctly, is that you used the middle sensor to *confirm* that your vehicle was moving along the line. However, imagine that this sensor was removed. What would happen? Eventually it might veer off until one of the edge sensors saw the line. Then you could correct course. Would this potentially allow you to remove a component and make your design less expensive? What would you gain by doing this? What would you lose? To be clear, this suggestion may be a bad one. But these sort of thought experiments can help you detect new possibilities for your design but also confirm your current design. Every time another option is a ‘bad idea’, it confirms that the current design is a good one. We prove almost nothing to be true or absolute in science. Instead, we merely prove other things wrong. And, each time we do, the prevailing ideas and theories become that much stronger.”

– Director of Research and Development, Smith & Nephew

“I am an Advanced Manufacturing Engineer at Smith & Nephew. I work in the Advance Healing group where I work on New product development projects designing/testing and manufacturing medical devices. My current product I am working on is manufacturing of Rotator Cuff shoulder repair instruments that surgeons use during their surgery. I have held positions in my career as R&D engineer, Development engineer and now manufacturing engineer. Robotics and automation are used all the time in the manufacturing environment at my company and it is great to see you are getting a chance to learn the basics.

This is a really cool project! First, I loved the process map. I use them all the time within manufacturing. It is a really great visual not only for logic based coding but also setting up and running a manufacturing line. I was able to easily follow the flow through each of the decision steps, it is simple and concise but gets all of the necessary information on it. It is really important to map out at a high level exactly what you need to do and helps you build and make a plan to execute the details later.

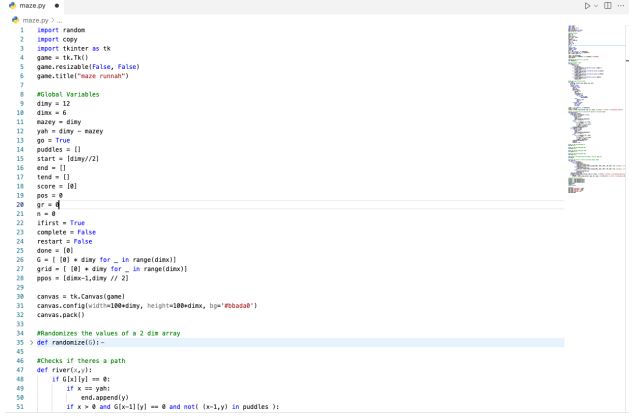

Coding was something I enjoyed learning in school, while sometimes extremely frustrating it is always great to see the finished product. Nothing beats spending hours on code trouble shooting and problem solving what has gone wrong to then finally figure it out and get it to work! Always great to see the progress.

I am curious how different your code would have been had you gone with 1 or 2 sensors vs the 3? It could have been a good exercise to plan out what the AGV would have looked like with only 1 sensor and if you could have accomplished the same thing. That could have been a way to drive down cost, figure out how to do the same with less materials.

Overall I was very impressed by your group, it was a very thorough presentation and I wish you all the best in your future! Awesome to see the passion for engineering come through in a project like this. Wish you the best in your next steps of education!”

-Advanced Manufacturing Engineer, Smith & Nephew

Industry Award: 1st Place High School Engineering Project

School: Uxbridge High School

Teacher: Mike Smutok